To measure the strength of manufacturing enterprises, production efficiency is an important dimension. Efficiency and quality are the foundation of the survival of an enterprise. Effectively improving production efficiency is the key to reducing production costs, and quality is the prerequisite for enterprise development. In the production process of products, it is not feasible to rely on a large amount of labor to improve efficiency in the 4.0 industrial era. Companies often use intelligent assembly lines, but if there is no reasonable line design, improving production efficiency is just empty talk, which will cause a waste of human resources. So how can intelligent assembly lines effectively improve production efficiency?

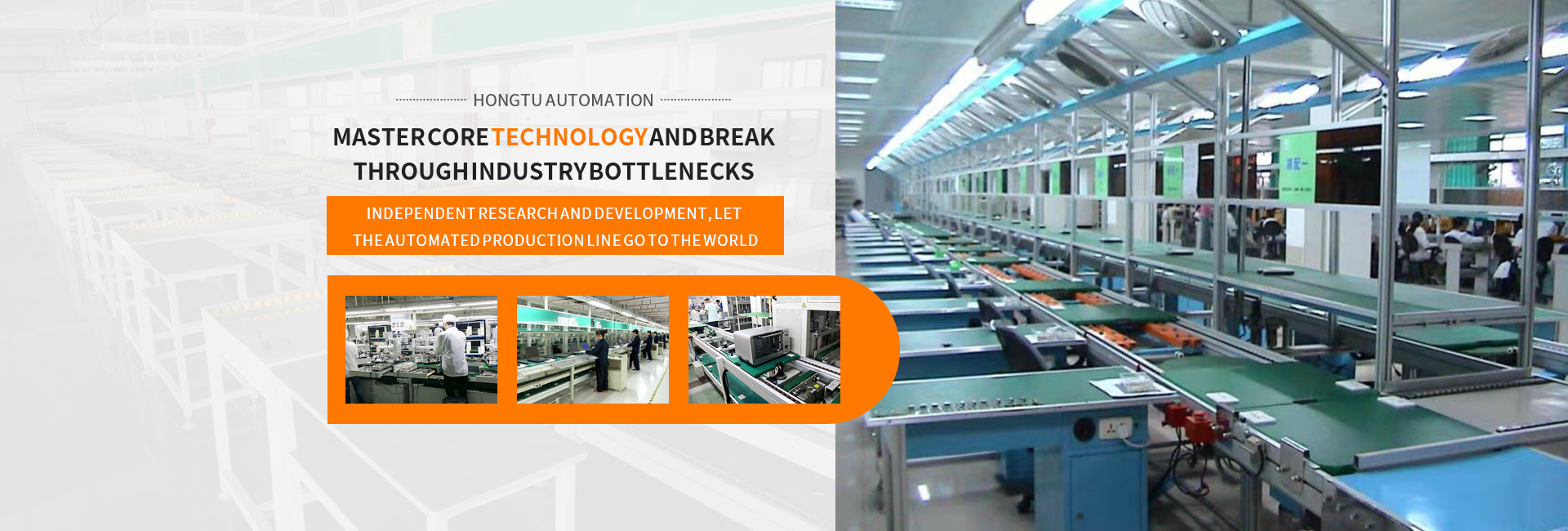

1. Design of intelligent assembly line

The intelligent assembly line must be combined with the actual situation of the enterprise, through site observation, product process analysis, and reasonable design of an assembly line that conforms to the enterprise's production and operation. Since the rationality of the assembly line directly affects product quality, the final efficiency cannot be improved, and the cost increases.

2. The layout of the intelligent assembly line

The layout of the intelligent assembly line is as simple as possible, and the line body is laid out in accordance with the workshop site and the working habits of the employees. If the line body is too complicated, it will cause inconvenience for the employees to operate, thereby affecting the production efficiency, and the intelligent assembly line will lose its meaning.

3. Production process management

Production management is an important link in the operation of an enterprise, and the operation of intelligent assembly lines also requires effective management. Standardized production and operation of employees, rational deployment of personnel, and establishment of a rapid response mechanism to respond to emergencies are all compulsory courses for management. The staff operates smoothly, the line body operates smoothly, and the production efficiency is evenly improved.

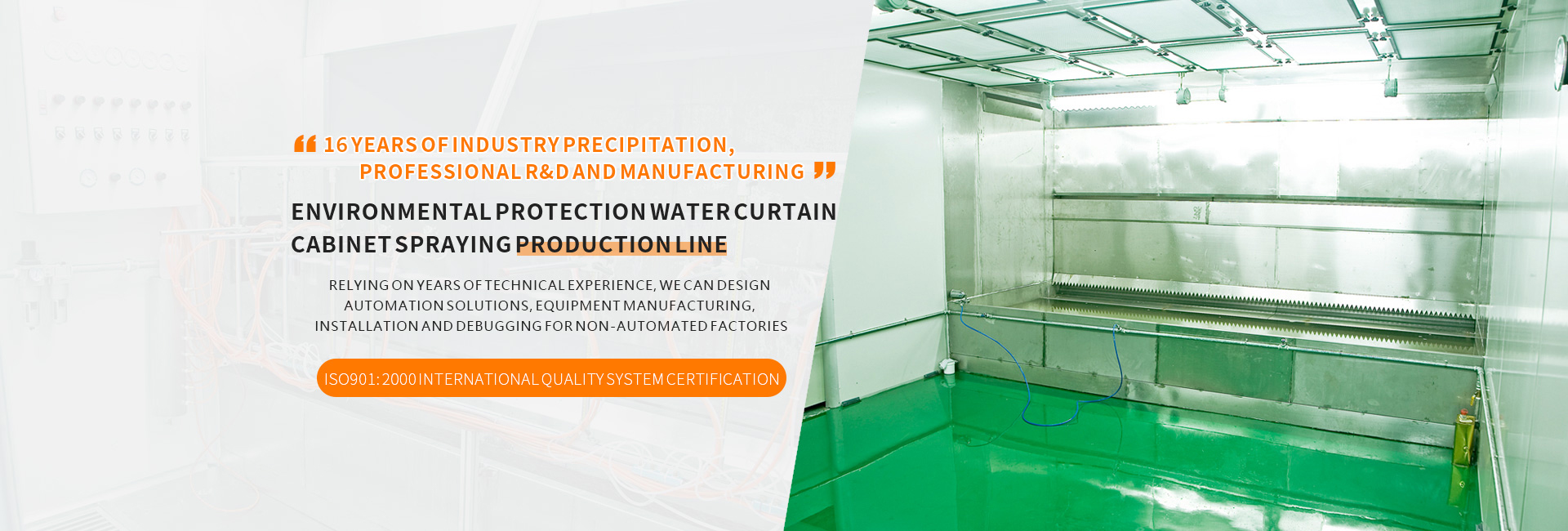

4. Regular maintenance of the intelligent assembly line

The intelligent assembly line also needs regular maintenance. Regular maintenance can effectively prevent excessive aging and wear of the line body. It is necessary to observe the easily worn parts of the line body regularly, and replace it in time if there are hidden dangers, so as to avoid the manpower and material resources caused by the failure of the intelligent assembly line. Waste loss. If the company cannot determine or repair it, the manufacturer or a qualified manufacturer should be retrieved for repair.

Based on the above 4 points, there are still traces of how to improve production efficiency. After mastering the intelligent assembly line method and regular warranty, improving production efficiency is just around the corner!